Snap Fit Design

I used DFM and DFA analysis and then designed an injection molded snap fit to save Shark Ninja $75,000 annually

Robotics Advanced Development team, Mechanical Engineering Co-op

I had the pleasure of working on the Robotics Advanced Development team at Shark Ninja working on the Fall 2020 line of autonomous robot vacuums. Due to a unique management structure, I had the opportunity and the responsibility to determine the projects and the tasks that would be most useful to the team and it’s long term goals.

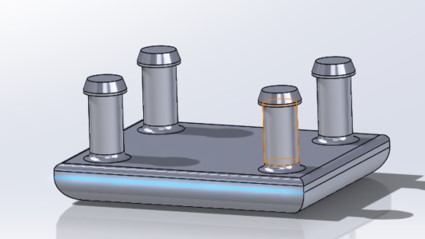

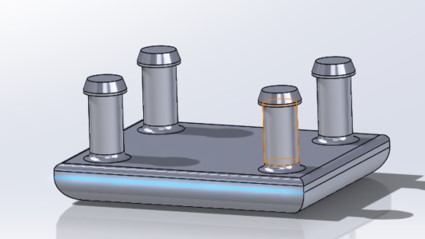

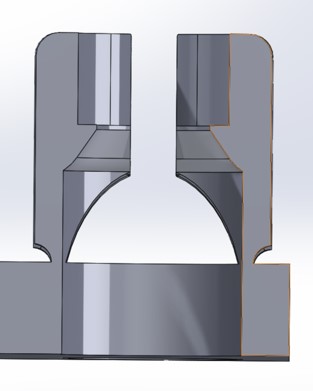

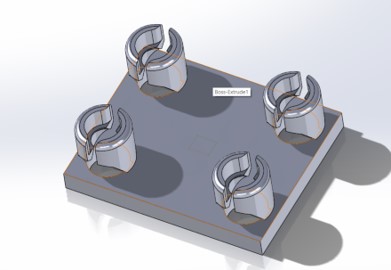

Snap Fits

This project was the result of a deep dive into a DFM and DFA study (using Boothroyd Dewhurst software) where I found 35 seconds of assembly time was spent on superfluous screws in the design. These snap fits were designed to replace multiple screws in the chassis assembly and would save $75,000 annually.