Shark Ninja Co-op 2020

I had an incredible experience working on the robotics Advanced Development team

Robotics Advanced Development Team, Mechanical Engineering Co-op

I had the pleasure of working on the Robotics Advanced Development team working on the Fall 2020 line of autonomous robot vacuums. Due to a unique management structure, I had the opportunity and the responsibility to determine the projects and the tasks that would be most useful to the team and it’s long term goals.

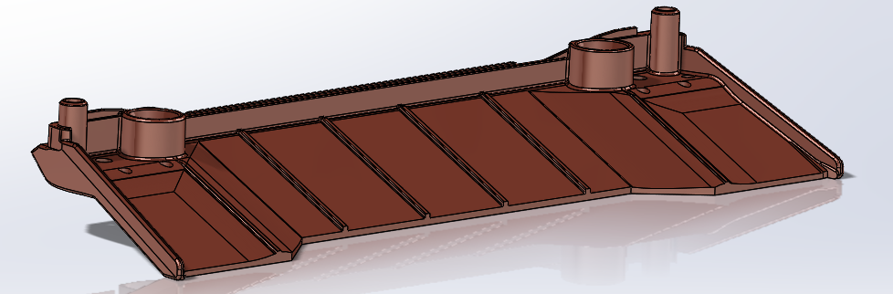

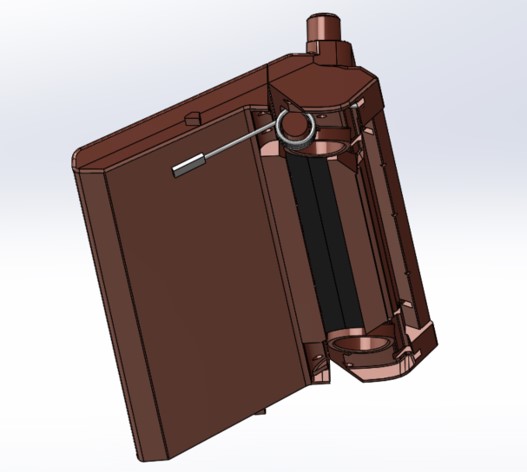

Dust Bin Redesign

“It was difficult to get my fingers

into the space where the dust was

clinging. I found it best to use

something to insert and try

to get the dust out”

-Consumer

“It was difficult to get my fingers

into the space where the dust was

clinging. I found it best to use

something to insert and try

to get the dust out”

-Consumer

For this project, I found that many users were complaining that they had difficulty emptying the dust out of their robot vacuums. I requested that I dive into the problem and solve it before we came out with the next model. This led me down a three month task of determining the causation of the problem, designing an effective solution, creating a test to validate that I had satisfactorily solved the problem, validating all other aspects of my design, coordinating with the manufacturing team in China, and getting the design and the tooling investment approved for mass production.

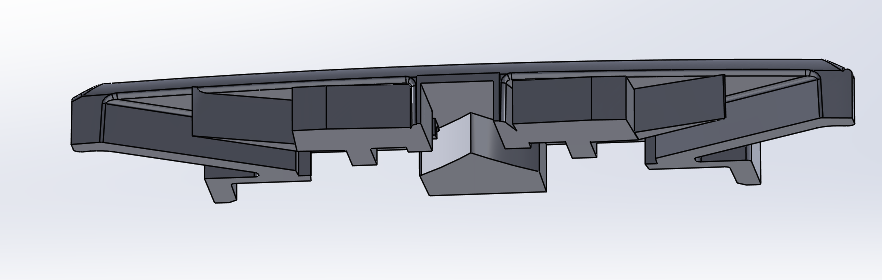

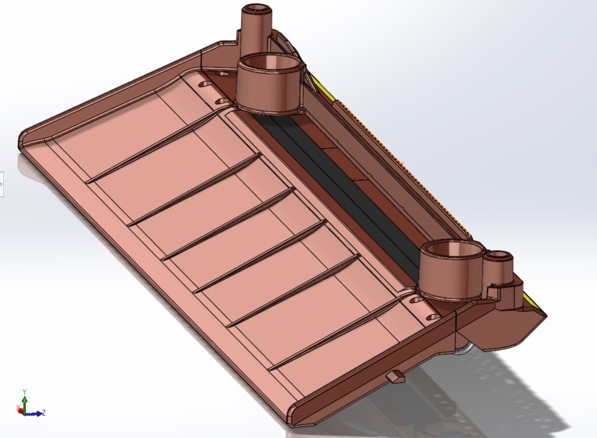

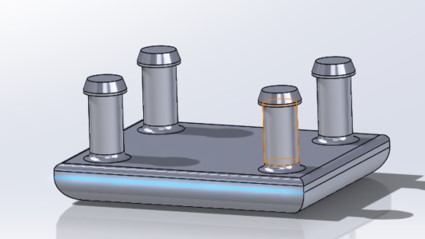

CAD design

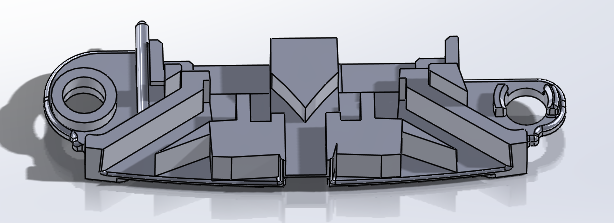

Test Rig

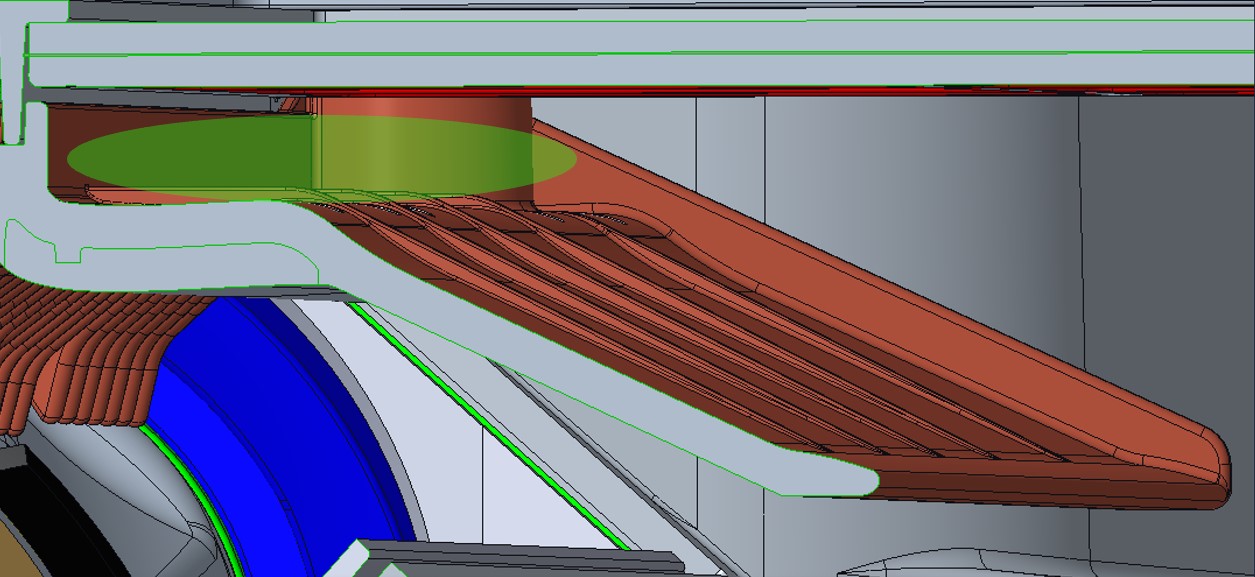

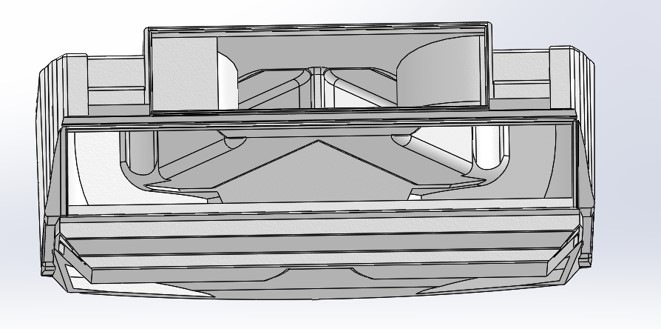

Airpath Optimization Project

For this project, I had the luxury of redesigning the entire dust cup from scratch and designing a future design that would read the benefits of a better airpath, improved cleaning performance, and larger dust cup volume. Initial prototypes were made but due to Covid and more urgent projects taking priority this design was never fully validated. In this project I gained a ton of experience in Solid works as I had to create this model from scratch.

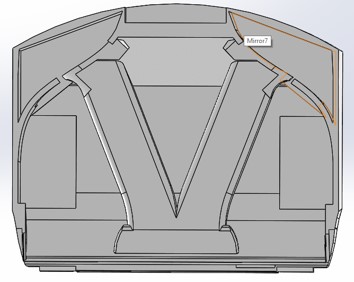

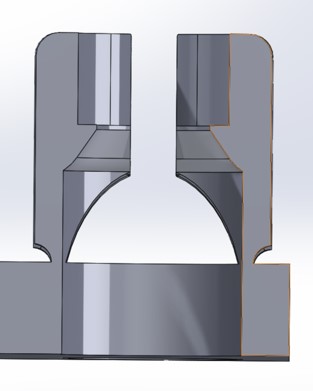

Infrared Receiver Project

Here, I tried to design a mirrored surface in the IR receiver housing that would split a small beam of light and direct it to two sensors. This would have improved the accuracy of the docking guidance system and result in improved docking performance. This design ended up being too costly to be brought to MP.

Pivoting Hair Wing

Here, I tried to solve the clogging problem above with a pivoting hair wing that would dump any clogs. This required designing a flexible rubber over mold into the part.

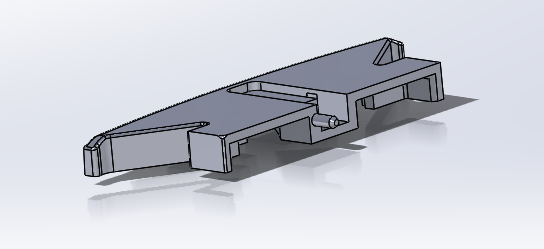

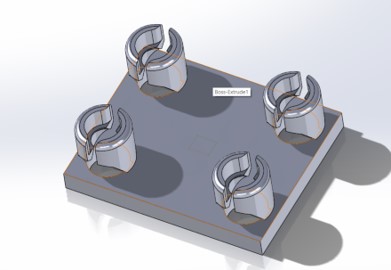

Snap Fits

This project was the result of a deep dive into a DFM and DFA study where I found considerable amount of assembly time was spent on a couple of superfluous screws in the design. These snap fits were designed to replace multiple screws in the chassis assembly and would have saved $75,000 annually.